The world of technology is ever-changing and constantly advancing, and one crucial component in this advancement is the use of alumina ceramics. Alumina, or aluminum oxide, is a commonly used material in the production of precision and technical ceramics due to its high-grade and purity. From electronics to aerospace, and from medical to chemical applications, alumina ceramics play a vital role in many high-tech industries. With companies like Advanced Ceramic Engineering (ACE) specializing in the manufacture and design of alumina components, it is clear that these engineered ceramics have a bright future ahead.

In the rapidly expanding semiconductor industry, alumina ceramics have become an essential material for various components and processes. With the demand for smaller and more powerful devices, the need for precision and reliability in semiconductor manufacturing has never been greater. This is where the unique properties of alumina ceramics come into play, making it an irreplaceable material in the production of semiconductor devices.

One of the primary uses of alumina ceramics in the semiconductor industry is in the production of circuit boards. These boards house the tiny electronic components that form the basis of all modern technology. Alumina ceramics are used in the manufacturing process because of their excellent electrical insulation properties, allowing for the efficient flow of current without any interference. They also have a high thermal conductivity, making them ideal for managing the heat generated by the components on the circuit board.

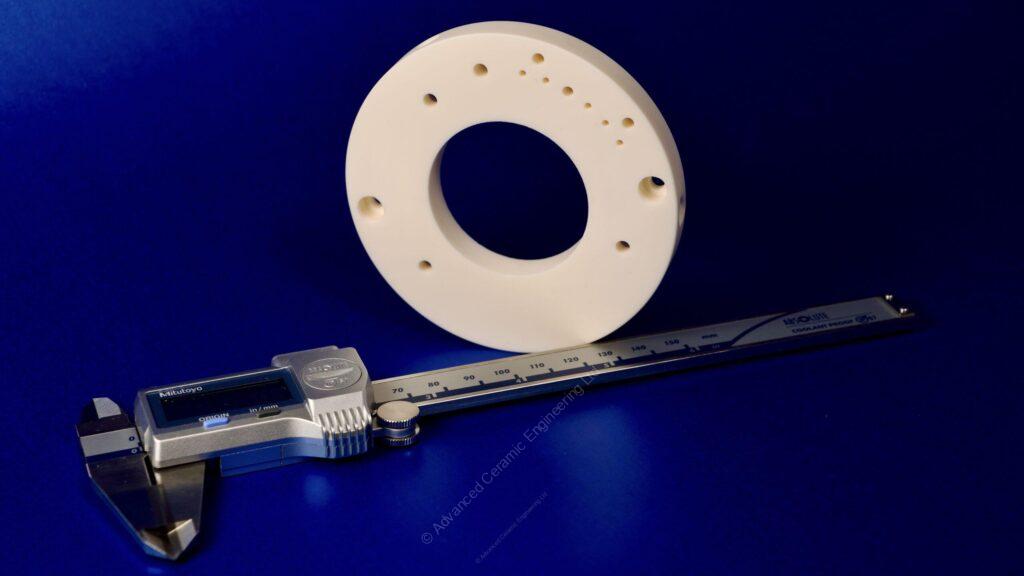

In addition to circuit boards, alumina ceramics are also crucial in other stages of semiconductor manufacturing, such as in etch and deposition equipment. The harsh conditions of these processes require materials that can withstand extreme temperatures, pressure, and corrosive chemicals. Alumina ceramics excel in these conditions, making them a reliable choice for critical components in semiconductor manufacturing equipment.

Moreover, as the demand for more advanced and innovative devices continues to grow, the need for better performing materials becomes increasingly significant. Alumina ceramics have unique properties that make them highly suitable for these evolving requirements. They have high strength and durability, ensuring the reliability and longevity of semiconductors. They are also highly resistant to wear and tear, making them ideal for use in abrasive environments.

With over 40 years of experience in the production and design of alumina ceramics, companies like ACE are at the forefront of innovation in this field. They continuously strive to develop new and improved alumina materials that can meet the ever-changing needs of their clients. With their experienced workforce and incorporation of the latest technologies, the future of semiconductor manufacturing with alumina ceramics seems