Isostatic pressing

UK & Europe wide.

Hot isostatic pressing (HIP) is a manufacturing process, used to reduce the porosity of metals and increase the density of many ceramic materials. This improves the material’s mechanical properties and workability.

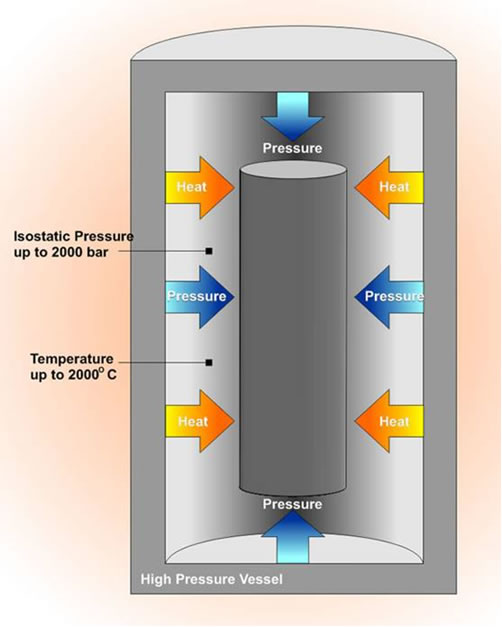

The HIP process subjects a component to both elevated temperature and isostatic gas pressure in a high pressure containment vessel. The pressurizing gas most widely used is argon. An inert gas is used so that the material does not chemically react. The chamber is heated, causing the pressure inside the vessel to increase. Many systems use associated gas pumping to achieve the necessary pressure level. Pressure is applied to the material from all directions (hence the term “isostatic”).

For processing castings, metal powders can also be turned to compact solids by this method, the inert gas is applied between 7,350 psi (50.7 MPa) and 45,000 psi (310 MPa), with 15,000 psi (100 MPa) being most common. Process soak temperatures range from 900 °F (482 °C) for aluminium castings to 2,400 °F (1,320 °C) for nickel-based superalloys. When castings are treated with HIP, the simultaneous application of heat and pressure eliminates internal voids and microporosity through a combination of plastic deformation, creep, and diffusion bonding; this process improves fatigue resistance of the component. Primary applications are the reduction of microshrinkage, the consolidation of powder metals, ceramic composites and metal cladding. Hot isostatic pressing is thus also used as part of a sintering (powder metallurgy) process and for fabrication of metal matrix composites,[1] often being used for postprocessing in additive manufacturing.[2]

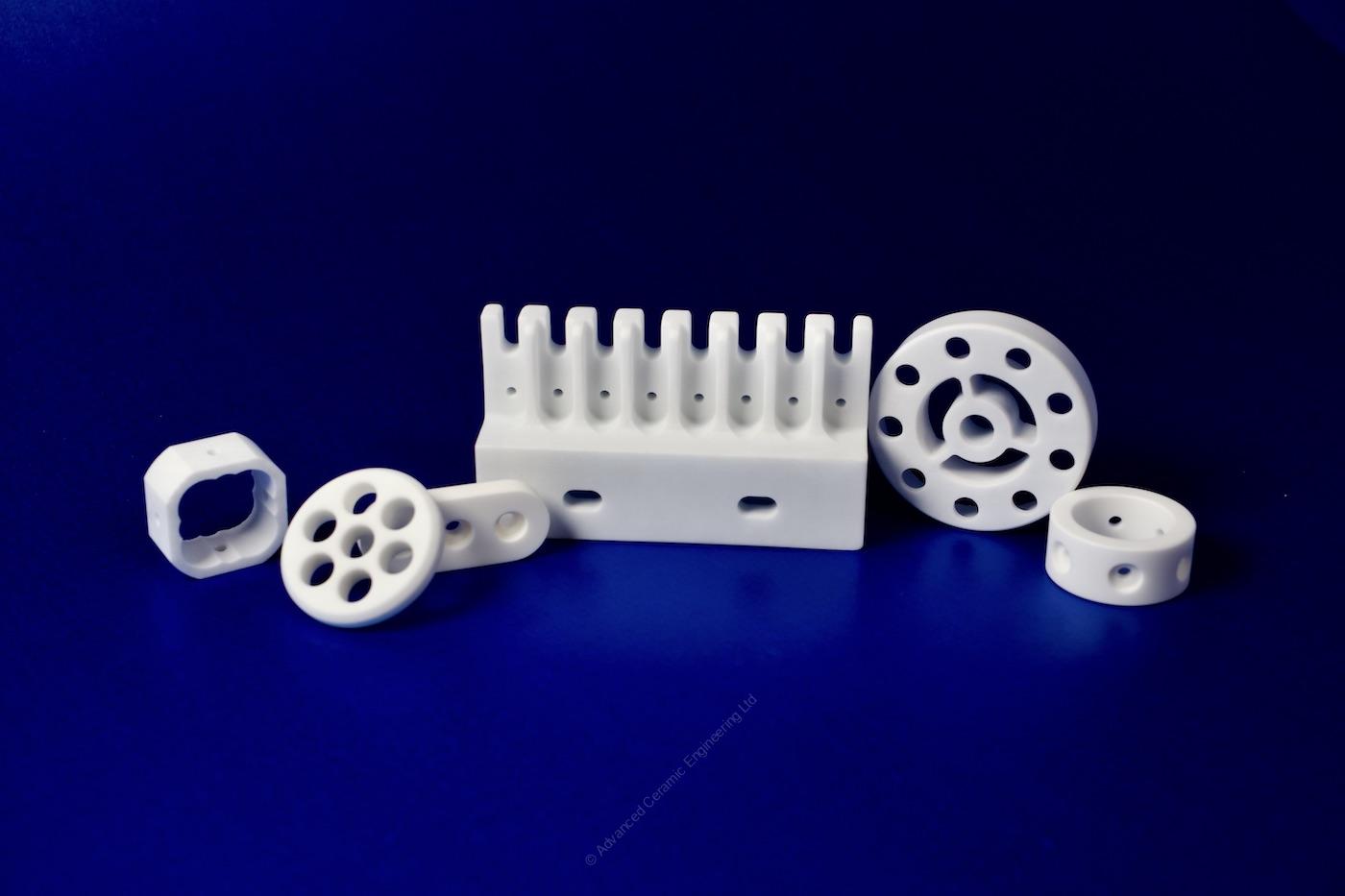

Alumina isostatic pressing is one of the most popular and consistent types of ceramic pressing. Due to the uniform pressure applied by the pressurised water, isostatic pressing gives a consistent pressure throughout the billets, both length-wise, and radially.

It is therefore very useful when making a number of components from the same billet, as it lends itself to achieving consistent shrinkage, grain size and density throughout a batch of components.

At present we can produce components up to 80 mm in diameter and up to 300 mm in length. We do hope to double our capacity – diameter wise – in the not too distant future.

- We supply UK & Europe wide

- 40 Years Experience

- Wide range of solutions