Welcome to the Advanced Ceramic Engineering company blog! We are thrilled to share with you our expertise and passion for precision and technical ceramics. With over 40 years of experience in the industry, ACE (as we like to call ourselves) is based in Northern Ireland and offers a wide range of alumina components throughout the UK. Our company specializes in the production and design of high grade and purity alumina ceramics, which are commonly referred to as precision ceramics, technical ceramics, advanced ceramics, or engineered ceramics.

At ACE, we understand the importance of providing high-quality ceramic components for a variety of industries. Our range of alumina materials has been specifically developed to meet the diverse service conditions required by industries such as electronics, aerospace, chemical processing, vacuum and semi-conductor, pump and valve, lasers and medical, and chemical and wear applications. Thanks to our advanced production techniques and high-grade materials, our ceramics are highly durable and able to withstand even the most demanding environments.

Our company was formed in 2002, following the closure of the former Wade/Seagoe Ceramics plant in Craigavon, Northern Ireland. This means that most of our employees are ex-Seagoe and have over 40 years of experience in the production and design of precision and technical ceramics. This experience and knowledge have been invaluable in keeping our company at the forefront of the industry.

We take great pride in being able to offer a wide range of alumina components UK wide, and also have the capability to custom manufacture to your specific requirements. At ACE, we believe that no project is too big or too small, and we are always eager to take on new challenges. Our team of skilled professionals is dedicated to providing excellent customer service and ensuring that your expectations are not only met but exceeded.

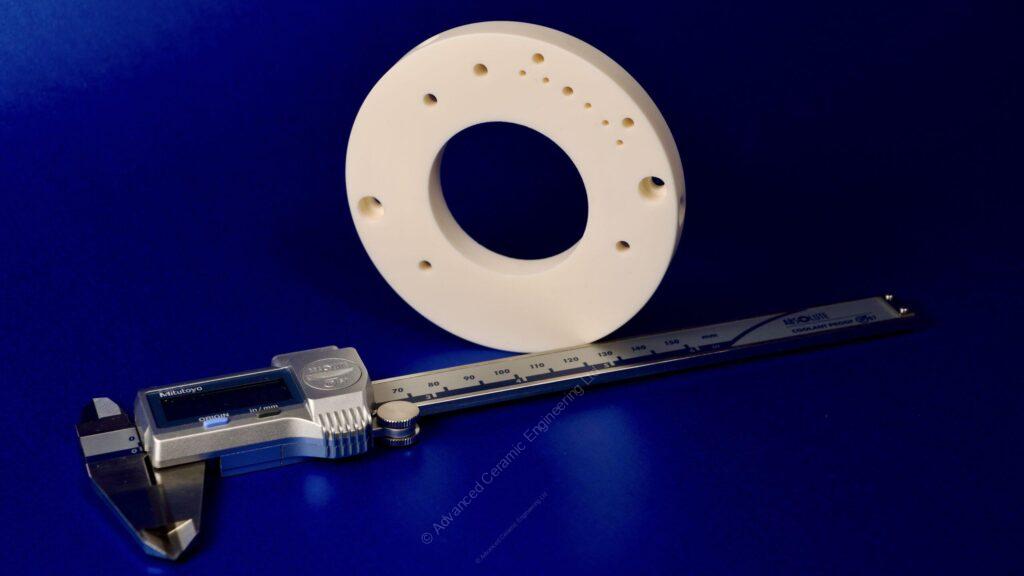

One of our key strengths at ACE is our production process, which has been refined and perfected over the decades. We use raw milled alumina to manufacture our ceramics and employ techniques like isostatic pressing, ‘green’ machining, sintering, and diamond grinding. These tried and trusted methods, combined with the latest innovations and an experienced workforce, make ACE a very formidable and cutting-edge company in the field of precision and technical ceramics.

We are also committed to continuously improving and advancing our production methods and materials. Our team is constantly researching and exploring new techniques and materials to ensure that our clients have access to the latest and most innovative products.

In conclusion, at Advanced Ceramic Engineering, we are proud to leverage decades